| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

PAKFORM MAKİNA SAN. VE TİC. LTD. ŞTİ.

BOSB BİRLİK SANAYİ SİTESİ 2. CADDE NO: 75 BEYLİKDÜZÜ / / İSTANBUL / TÜRKİYE

|

Contact Info: +90 532 312 3721

|

Hall: 1

Stand: 105B6

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

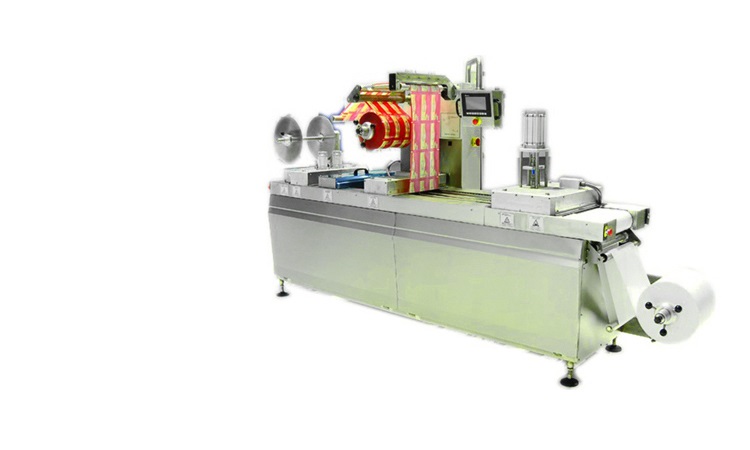

Since 1968, thousands of custom-made machines have been manufactured in various countries of the world in the machine manufacturing sector from the past to the present, our PAKFORM MACHINE company was founded in Istanbul, leaving 54 years behind, we have manufactured 4200 automatic thermoforming packaging and packaging machines, we have achieved success in 72 countries and Turkish Sundays with both service and spare parts supplies. We are ambitious in the production of packaging machines because, what is important for us is your satisfaction! We make the best design in Food Packaging and Medical Packaging without Compromising on Quality. Pakform Medical Packaging,Food Packaging,Industrial Parts ...

Advantages of PAKFORM Thermoforming packaging machines What are your expectations from thermoforming packaging machines? Small footprint Quick mold changing Special packaging forms High efficiency and fast operation PAKFORM offers you a diverse range of machines that can meet your specific needs. Areas of use: Thermoformed Dairy Products, Meat Products, Delicatessen Products, Frozen Foods, Honey, Jam, Water, All Kinds of Sauces, Seafood (Shrimp, Anchovy, Squid, Various Fish, Various Frozen Salted and Smoked Fish, Vacuumed and Sauced Fish), Bakery Products Ravioli, Pastry, Pastry, Various Cookies and Pastries, Kadayifs..), Medical Products (Injectors, Gauze and Hydrophilic Cloths, Surgical Instruments, Medical Covers and Medical Clothes), Industrial Products and Machinery Parts, Bearings, Screws..etc. . Dimensions: between 3m-4m mechanical stroke: 10-22 strokes (minute) Mold material: 5083-7075 Aluminum PLC - Omron Pneumatics : Mindman Electrical materials: Telemecanique / Merlin Gerin / Moeller Electrical equipment: 380 V-3 Phase-50 Hz Electricity consumption: 12-15 kw / hour (average) Bottom Foil :Hard foil PS +PE,PVC+PE Soft Foil PA +PE Top Foil :Medical paper , Tyvec , Aluminum ,PP +PA options Automatic filling system - Dosing and product loading systems - Coding and printing systems (Thermal printers, Flex Printer, Ink-Jet etc.) - Checkweigher - Chiller - Vacuum Pump - Modified atmosphere packaging (MAP) - Printed film registration - upper film - Discharge unit for liquid products - Other options upon request

No represented companies found.

The company has no registered brand information.

TR

TR